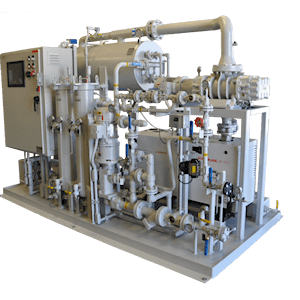

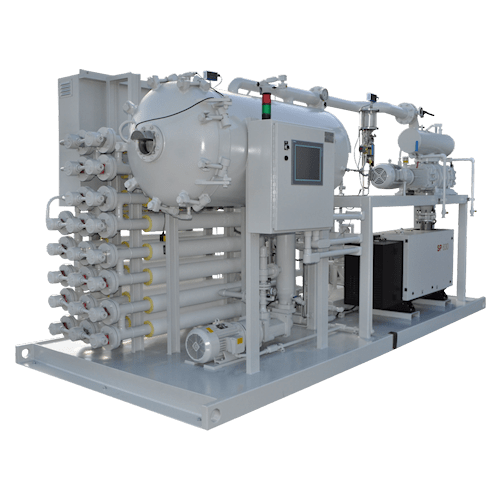

The SES320 family of stationary and mobile vacuum oil purifiers are used to prepare dielectric fluids for service, as well as vacuum dry and fill high voltage oil cooled equipment. After 30 years of production, the SES320 family can be found in power generation, transmission, distribution, and transformer manufacturing industries world-wide.

All SES320 models are fully customizable conditioning systems and are designed to “single pass” oil processing performance standards to accommodate all transformer maintenance and commissioning requirements. The SES320 incorporates an optional adsorbent treatment stage to add oil regeneration capability to the standard SES320 capabilities. The SES320 series includes a wide variety of mounting options.

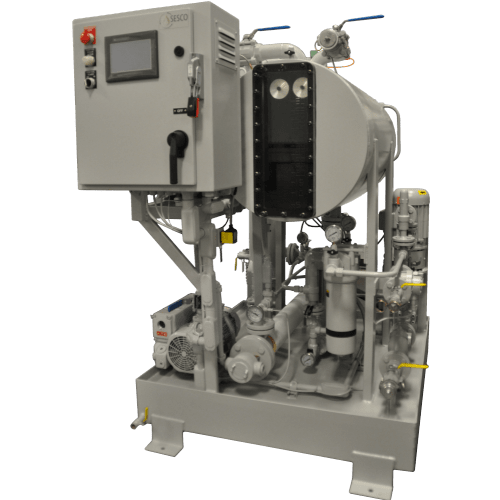

The SES322 is targeted for drum quantity specialty dielectric or lubricating fluids that requires de-gasification and or polor contaminant removal or color correction. The SES32 offers both 55-gallon multi-pass batch and single pass processing modes.

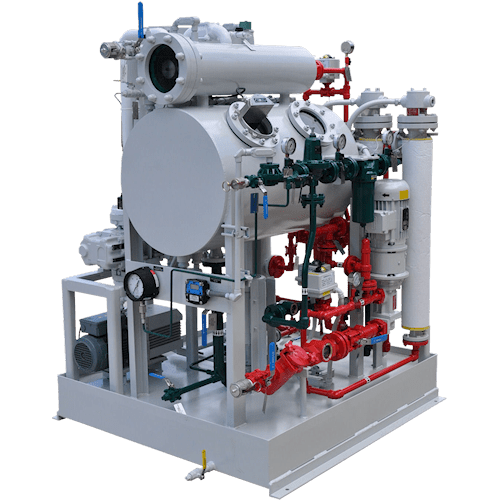

The SES323 is a high discharge pressure version of the SES322 batch system targeted for high voltage cable oil filling applications.

SES320 |

SES322 |

SES323 | |

|---|---|---|---|

|

|

|

|

Description |

Fully Customizable Dielectric Fluid Conditioning & Regeneration, & Transformer Dry Out Systems 900-3000 GPH |

Specialty Fluids Multi-Pass 55 Gallon Batch Vacuum Degasification and Dehydration System |

Oil Filled Cable Regeneration, and Filling System |

Model NumberLinks |

|||

Processed FluidTypes |

Petrolium Based Natural Esters Synthetic Esters Silicones |

Petrolium Based Natural Esters |

Cable Oils Syntethetics & Petrolium Based |

Functions |

Single Pass Oil Conditioning Optional Multipass Reganeration |

5 - 55 GAL Multi-Pass Batch Processing Mode 3 GPM Single Pass Processing Mode Optional Use Adsorbent Treatment Stage 250 CFM Vacuum Connection Aparatus Evacuation and Vacuum Filling |

55 GAL Multi-Pass Batch Optional 1 GPM Single Pass Oil Conditioning & Regeneration Vacuum Dry-Out |

Mounting Options |

Skid |

Skid Canvas Outdoor Enclosure |

Skid Bumper Hitch Cargo Trailer Gooseneck Cargo Trailer ISO Container |

Follow