The SES328 family of vacuum line cold traps are targeted as tool to help quantify the rate and volume of water extraction during the transformer vacuum dry out process. The sublimated water vapor condenses and frezes when it contacts the trap extreme cold surface. An extraction rate is determined by periodiclydefrosting to melt the ice and measuring the collected water over a given time period. Refrigerated and liquid nitrogen cooled traps are available. Single stage refrigerated traps are used for trapping between vacuum pump stages. Liquid nitrogen and two stage (Cascade) refrigerated systems are cold enough to trap at evacuation pressures.

SES328 Highlights

High-Efficiency Trap Design

Standard Bypass for Continuous Evacuation

Stainless Steel Trap Construction

Low-pressure Drop Design

Condensing Action Enhances Dryout Process

Liquid Nitrogen Cooled Vacuum Line Water Vapor Cold Trap

The liquid nitrogen cold trap uses bottled liquid nitrogen as a chilling media to provide the necessary vapor trapping surface temperatures. The extracted water and oil vapors are trapped on the surface of a liquid nitrogen-filled thimble. At measuring intervals, the thimble is removed. Ice is collected thawed for water measurement. A trap bypass line permits continuous evacuation during measuring cycles. The nitrogen trap is inexpensive, small, efficient, and maintenance free but must be defrosted manually. Handling the liquid nitrogen is very easy and safe with the standard protective clothing provided.

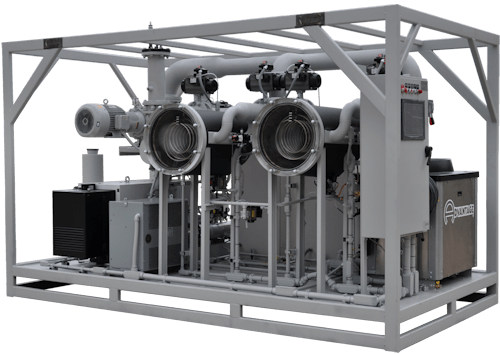

Standalone and system integrated refrigeration system cooled vacuum line water vapor cold traps.

Refrigerated cold traps are available with single and two-stage refrigeration systems. Traditional two-stage "cascade" systems produce trapping temperatures of ~-80°C and efficiently trap water vapor at pressures as low as 0.15 torr. Cascade traps should be positioned at the inlet of the vacuum booster pump. Less expensive and complex single stage refrigeration system traps are available. Single stage traps produce trapping temperatures of ~-45°C and efficiently trap water vapor at pressures as low as 0.5 torr. It is recommended that single stage traps be positioned between the vacuum backing pump and the booster where the pressure remains high enough to trap through the entire evacuation pressure range. Automatic defrost cycles are included on both versions. The cascade version provides colder surface temperatures making it more efficient at lower pressures. Both systems must be mounted in a separate trailer or packaged with the oil processor trailer.

The SES328R refrigerated cold trap can be stand-alone skid mounted, stand-alone cargo trailer mounted or when van mounted integrated into the external vacuum line of a SES320 conditioning system. SES328N-9.25-BP

SES328R

Skid Mounting

Dry Van Trailer Mounting

Cargo Trailer Mounting

Follow