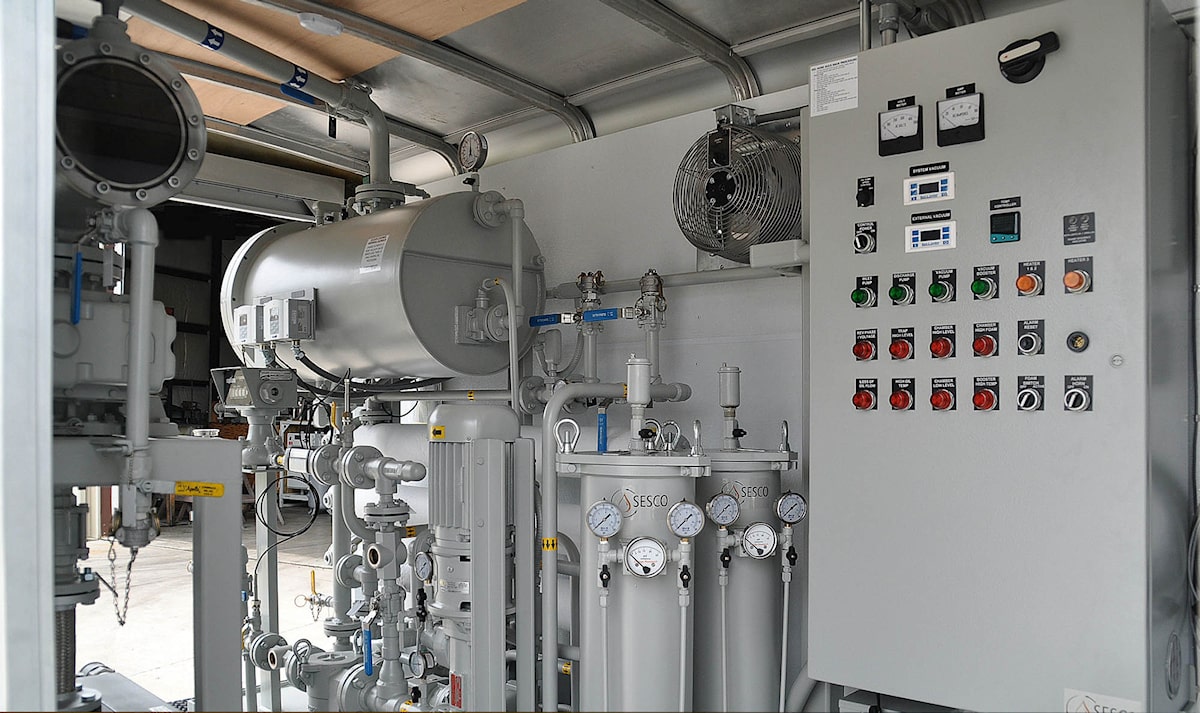

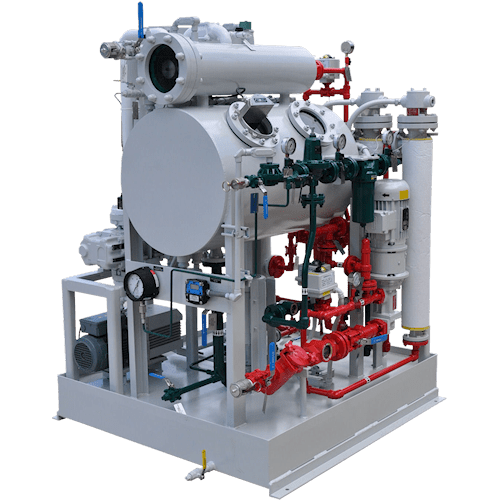

The SES323 is a dielectric oil conditioning and regeneration system specifically designed for filling and maintaining high power cable insulating/cooling fluids. The SES323 conditions dielectric fluid for use by removing dissolved water, gas and particulate. An optional adsorbent treatment phase is also provided to correct the total acid number and color if necessary.

The standard configuration provides both straight through single pass processing and multi-pass processing using the integrated 55 gallon stainless steel reservoir.

SES323 Highlights

Conditions Mineral & Synthetic Dielectric Cable Fluids

Straight Through Single Pass Processing

Multi-Pass Batch Processing

Viscosities up to 2000 SSU

Built-in 100% Safety Spill Retention

130 CFM Vacuum Capacity

External Vacuum Connection Available

Cable Oils and Other Specialty Dielectric Fluids SES323 is used as a cable dielectric fluid conditioning system to prepare mineral-based and synthetic cable dielectric fluids for high voltage cable service. Fluid insulating properties are improved to acceptable levels by removing dissolved water, dissolved gas, and solid matter contamination. If necessary, polar contaminants can also be removed using the process loop optional activated alumina cartridge filter. The discharge pressure is adjustable to 175 PSI to handle challenging cable-filling requirements. The SES323 system is specifically designed to accommodate a wide range of cable dielectric fluids including the more viscous fluids such as DF500. The SES323 has enough vacuum, heating, storage capacity to permit both batch and single pass processing. In batch mode an internal 304 SS storage tank is used to provide multiple passes through the process loop. Batch quantities can range from 10 to 60 gallons. Single-pass mode requires the batch reservoir to be empty and operates at a reduced flow rate to provide straight-through processing. Batch and single pass processing modes switch selectable from the control panel. An adsorbent treatment stage is provided to remove acids, color bodies, sludge components and other polar contaminants if necessary. A bypass circuit is provided. Use of the adsorbent treatment stage is optional. The housing accepts standard flat gasket sealed Fullers Earth and Activated Alumina cartridges. The SES320B heating system uses high surface area heating elements to provide gentile low watt density indirect oil heating. A digital PID temperature controller is used to provide accurate panel adjustable temperature control. Flow and high-temperature system interlocks are provided for worry-free fail-safe operation. Need a vacuum system? Whether it's for everyday use or emergency use the SES320B has an isolated external connection allowing it to be used as a stand-alone 130 CFM vacuum system capable of achieving pressures as low as 0.1 torr. A panel mounted full-scale digital vacuum gauge is provided to monitor the vacuum system pressure. The SES320B skid is designed to contain minor drips and major spills. The skid integrated tank provides 100% containment of any potential system spill. Including the entire volume of the 65-gallon batch tank. 180 GPH (680 LPH) 65 Gallon Capacity 0.5μ @ β75 Polar Contamination (Optional treatment stage)

The SES320C can be stationary skid-mounted or packaged in an easy-to-tow cargo trailer for mobile applications.Dual Processing Modes - (Panel Selectable)

Adsorbent Treatment Phase

Accurate Fail Safe Oil Temperature Control

Stand Alone Vacuum System

Built-in 100% Safety Spill Retention

Treatment Stages

Oil Heating

Polar Contaminant Adsorption (optional)

Filtration (3μ β200)

Vacuum Dehydration & Degasification

Filtration (0.5μ β75)

Results

Specifications

Processing Rate

Batch Mode

Single Pass Mode

60 GPH (226 LPH)

Processed oil quality

Dielectric Strength

(ASTM-D1816-84A 2mm gap> 60 kV - (Dielectric Fluids)

Moisture Content

Typically 1 - 10 ppm

Total Gas Content

< 0.25%

Particulate Content

Effect on oil properties

will vary with the application

purification process

Watt Density

11.5 Watts/in2

Temperature Range (Adjustable)

120 F° ( 49 C°) to 190 F° ( 88 C°)

Vacuum Limits

0.1 Torr

Vacuum Capacity

130 CFM @ 0.5 Torr

Suction Lift

12 ft

Discharge Pressure

Adjustable 40 - 175 PSI

dimensions

English

55” W x 55” D x 73” H

Metric

140 cm W x 140 cm D x 185 cm H

CONNECTIONS

Inlet

1.25 FNPT

Discharge

0.75 FNPT

Vacuum

2" MCAM

Power Requirements

480V/3PH/60HZ

25 A

240V/2PH/60HZ

50 A

230V/1PH/60HZ

80 A

60 A @ 6 kW

WEight

English

2850 lbs (Dry)

3294 lbs (Full Batch)

Metric

1293 kg (Dry)

1494 kg (Full Batch)Processing Modes

Operating Voltage

Available Add-ons

Skid Mounting

Cargo Trailer Mounting

Follow